+8618680445103

+8618680445103

Free Standard Samples can be provided for you to check the quality.

Leave Your Message

Metal containers are essential in various industries for packaging, storage, and transportation. They offer durability and a barrier against external factors, ensuring the safety of their contents. According to a recent report by Smithers Pira, the global market for metal containers is projected to reach $150 billion by 2025, reflecting a growing demand in food, beverage, and chemical sectors.

Expert in metal packaging, Dr. Emily Grayson, states, “Metal containers provide unmatched protection, but we must consider their environmental impact.” This highlights a critical concern in today's market. While metal containers are recyclable, the energy consumed in production raises questions about sustainability. Companies are navigating these challenges by exploring eco-friendly materials and practices.

The versatility of metal containers makes them a preferred choice for many businesses. They come in various shapes and sizes, accommodating a range of products. However, as the industry evolves, it's crucial to address both functionality and environmental stewardship. Balancing these factors can lead to innovative solutions in metal container usage.

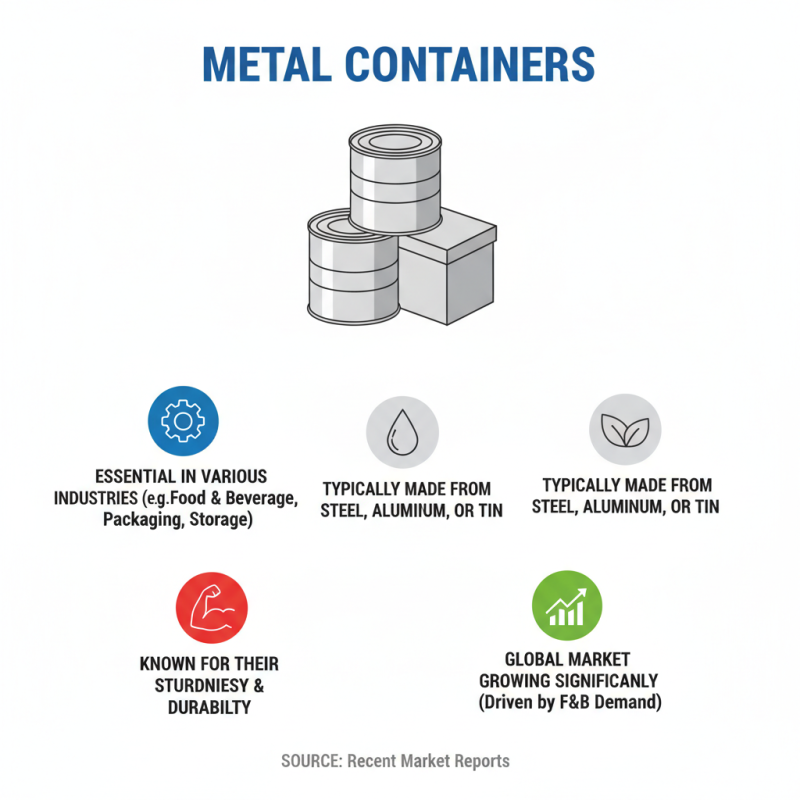

Metal containers are essential in various industries. They serve multiple purposes, from packaging to storage. These containers are typically made from steel, aluminum, or tin. Their sturdiness is a key characteristic. According to recent market reports, the global metal container market is projected to grow significantly, driven by demands in the food and beverage industry.

The durability of metal containers makes them ideal for preserving contents. They can withstand extreme temperatures and resist corrosion. Research indicates that nearly 70% of metal containers are recyclable. This aspect is increasingly important as sustainability becomes a priority. However, recycling processes can be imperfect. Not every facility effectively separates and processes metal materials.

Tips for using metal containers include ensuring proper sealing to prevent leaks. Regularly inspect containers for dents or rust, as these can compromise integrity. When choosing containers, consider the size to minimize waste. Smaller containers often lead to better inventory management, as they encourage use.

Metal containers come in various forms, each serving unique purposes across different industries. A common type is the tin can, often used for food and beverage storage. According to a report by Smithers Pira, the global market for metal packaging is expected to reach $180 billion by 2024. This growth highlights the demand for durable, recyclable options in packaging.

Another important type is steel drums, commonly utilized in chemical and industrial applications. These drums are robust and can hold large quantities, ranging from 5 to 55 gallons. However, improper handling can lead to leaks or contamination. Care must be taken when transporting hazardous materials in these containers. Additionally, aluminum containers, such as those used for aerosols, have skyrocketed in popularity. They are lightweight yet sturdy, making them ideal for personal care and household products.

The specific use of metal containers is often dictated by their ability to protect contents from external elements. However, the recycling rate for metal packaging is not as high as it should be. In 2022, data showed only 70% of metal containers were recycled in the U.S. This raises questions about consumer behavior and industry practices. The conversation around sustainability in metal containers is ongoing. New innovations may emerge, but challenges remain.

| Type of Metal Container | Material | Common Uses | Advantages |

|---|---|---|---|

| Metal Cans | Aluminum, Steel | Beverages, Food, Chemicals | Lightweight, Durable, Recyclable |

| Barrels | Steel, Stainless Steel | Liquids, Chemicals, Oil | Strong, Large Capacity, Easy to Store |

| Drums | Plastic, Steel | Industrial Materials, Chemicals | Sealable, Chemical Resistance, Versatile |

| Tin Cans | Tin Coated Steel | Food Preservation | Corrosion Resistant, Inexpensive |

| Metal Boxes | Aluminum, Steel | Storage, Packaging | Reusable, Durable, Protective |

Metal containers are essential in various industries. Their manufacturing involves several detailed processes. Typically, these include stamping, welding, and surface treatment.

Stamping starts with flat metal sheets. The sheets are cut and formed into specific shapes using powerful presses. This process is crucial and can produce containers efficiently. The global metal container market was valued at approximately $85 billion in 2022. Many projections suggest that it will grow over the next few years.

Welding follows stamping. It ensures the pieces of metal are securely joined. This stage is vital for the container's integrity. Surface treatments come next. They enhance durability and protect against corrosion. However, some methods can be hazardous to workers and the environment. Industry standards emphasize the need for safer processes. Balancing efficiency and safety remains a challenge in metal container manufacturing.

Metal containers are widely used across various industries. Their durability makes them ideal for storage and transportation. In the food and beverage sector, metal containers maintain product quality and extend shelf life. According to a 2021 industry report, 75% of consumers prefer metal packaging for beverages and food. Metal can completely seal contents from the environment, which reduces spoilage.

In the chemicals and pharmaceuticals industries, metal containers are essential. They ensure safe handling of hazardous materials. A study showed that metal packaging reduces contamination risk by over 60%. However, the initial cost of metal containers can be higher compared to alternatives. Companies must weigh long-term benefits against upfront expenses. This investment often leads to better safety and sustainability outcomes.

Environmental concerns also arise with metal containers. While they are recyclable, the recycling process can be energy-intensive. A review indicated that 70% of energy used in recycling comes from non-renewable sources. Companies face pressure to improve their sustainability practices. They must find a balance between using metal containers and reducing their environmental impact. As industries evolve, the dialogue around metal container usage continues to grow.

Metal containers play a significant role in our daily lives. They are widely used for packaging food and beverages. Their durability is a key advantage. However, the environmental impact of metal containers cannot be ignored. Producing these containers often involves extracting raw materials. This process can lead to habitat destruction. Additionally, mining operations can pollute local water sources.

On the sustainability front, metal containers have recycling potential. Aluminum and steel can be recycled numerous times without losing quality. In fact, recycling reduces energy consumption significantly. But the reality is that recycling rates are often lower than desired. Many people still do not recycle properly. This leads to waste in landfills. Education on proper recycling practices is essential.

Despite their benefits, metal containers also have a footprint. The manufacturing process emits greenhouse gases. The transport of these containers contributes to carbon emissions. It’s a complex issue. Balancing convenience and sustainability remains a challenge. As consumers, we must be mindful of our choices. The path toward responsible usage is still in progress.