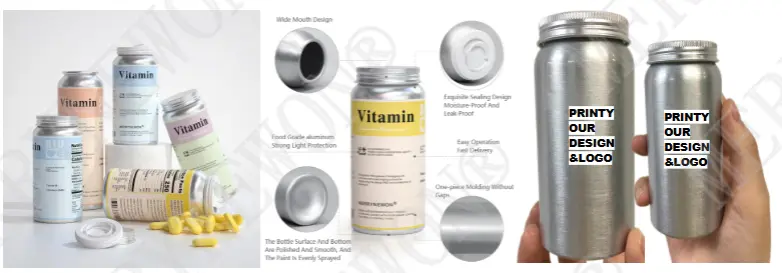

- Prevent scrapping: Equipped with a one-time seal ring, unopened drugs stay free from contamination. The bottles block oxygen and water, extending drug shelf life by 30% and avoiding post-production deterioration.

- Cut costs: 40% lighter than glass bottles, helping Wholesalers reduce single-batch shipping costs by 15%. The wide-mouth design is compatible with filling machines, preventing jams during small-batch production for factories.

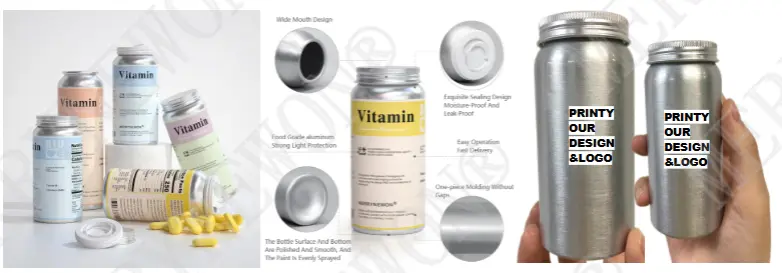

- Easy customization: Can print logos and instructions, with a minimum order quantity (MOQ) of 5,000 units—perfect for small and medium-sized brands launching trial sales.

- Enhance value: Features an industry-leading design with a premium feel, helping high-end health products increase end-market premium by 20%-30%.

- Large capacity: Up to 930ml, suitable for large cans of probiotics. Its strong seal prevents leakage during long-distance transportation.

- Flexible ordering: MOQ of 5,000-10,000 units, supporting color printing and gradient spray painting for custom brand colors.

- Enhance value: Features an industry-leading design with a premium feel, helping high-end health products increase end-market premium by 20%-30%.

- Large capacity: Up to 930ml, suitable for large cans of probiotics. Its strong seal prevents leakage during long-distance transportation.

- Flexible ordering: MOQ of 5,000-10,000 units, supporting color printing and gradient spray painting for custom brand colors.

- Meets standards: The easy-tear lid requires no tools, speeding up drug retrieval in pharmacies. The internal thread seal meets GMP requirements, avoiding audit failures for factories.

- Recyclable: 100% recyclable aluminum, useful for brands preparing ESG reports.

- High supply capacity: MOQ of 10,000 units with a monthly output of 500,000 units, ensuring no stockouts for factories’ large-batch production.

- Save trial production costs: MOQ of just 3,000 units, cutting trial production costs by 40% for small/medium factories testing new drugs or brands trialing new formulations (e.g., single-dose emergency drugs).

- Less hassle: Can be customized into child-resistant bottles or inhaler canisters. Wholesalers can cover multiple categories with one stock order, no need to manage multiple supply chains.

- Transportation-resistant: 6 times more shatterproof than glass bottles, reducing damage rates from 5% to below 0.5% when shipping to rural pharmacies—minimizing after-sales compensation. Also complies with FDA and EU GMP standards for export, no extra modifications needed.

- Faster production: Industrial-grade material is lightweight yet durable (unbroken after a 1.2-meter drop), boosting assembly line filling efficiency by 30% for large factories and preventing deformation during warehouse stacking.

- Export cost savings: Complies with global standards, avoiding customs compliance barriers. 20% lighter than traditional bottles, reducing container shipping costs per cabinet by 12%-18% (weight-based pricing).

- Strong adaptability: The user-friendly lid works with pharmacy automation equipment. Supports multi-language instruction printing, ideal for international brands. From design to mass production in just 15 days, helping brands seize market opportunities quickly.

MERRYNEWON® offers more than just products—it provides solid guarantees:

- Production capacity: 2 million units monthly, capable of fulfilling urgent orders from large factories.

- After-sales support: A damage rate ≤0.3% during normal transportation, with compensation for damages.

Whether you’re a factory needing large-scale production, a brand seeking premium positioning, or a wholesaler prioritizing stability,

MERRYNEWON® has tailored solutions to help you save money and operate with peace of mind.

+817089618688

+817089618688