+817089618688

+817089618688 Luxury in Aluminum: Keva’s Signature Perfume Bottles

The beginning of the cooperation story

Keva is an excellent perfume brand from Indonesia, specializing in high-end fragrance and essential oil products. Initially, they have been using glass bottles as packaging, but with the brand upgrade and the growth of market demand, the limitations of glass bottles gradually emerged: Fragile: easy to break during transportation and use, increasing losses. Heavy: Glass bottles are heavy, resulting in high logistics costs. Inconvenient to carry: For consumers, glass bottles are not convenient to carry. So, Keva began to look for a lighter, safer, and more brand-friendly packaging solution to upgrade their product packaging.

Keva's doubts

- Can the Aluminum bottle maintain the quality of the perfume?

- Is there a high-end craftsmanship?

- What is the visual effect?

Business Link

At MERRYNEWON, when faced with unclear customer needs, our team takes a step-by-step guidance approach to help them clarify their ideas and provide professional advice.

Step 1: Keva provides some simple size requirements and reference pictures of several glass bottles.

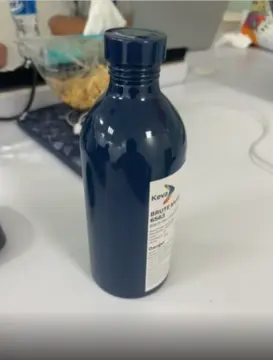

◄The left picture shows Keva's original product packaging and bottle stopper design.

Step 2: In combination with Keva’s brand tone and design style, we recommended different aluminum bottle shapes and introduced a variety of process options such as spray painting, silk screen printing, offset printing, and electroplating.

►The picture on the right shows a reference sample bottle provided by MERRYNEWON.

Step 3: The collision between Keva’s design concept and MERRYNEWON’s 3D rendering effect.

◄The left picture is Keva's design draft.

The picture below is a 3D rendering provided by MERRYNEWON (our design team).

Step 4: Confirm the bottle stopper and start the aluminum bottle proofing stage.

►The picture on the right shows the size and style of the bottle stopper finally confirmed by Keva. *Needs to fit the aluminum bottle.

Prototyping Challenges: Solving the Difficulties in Customization

Challenge 1: Subjectivity of color customization the color of aluminum bottles may vary under different light, and high temperature baking during production will affect the color. We maintained close communication with Keva and made multiple rounds of adjustments to achieve the most ideal color effect.

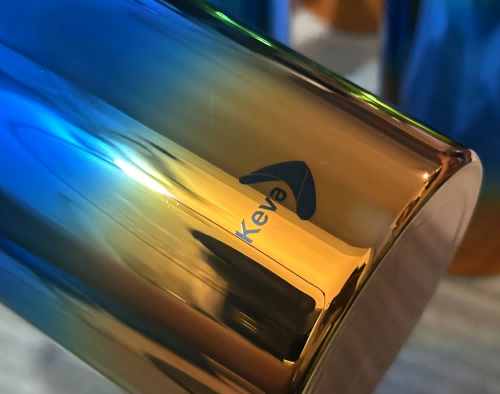

Challenge 2: Accuracy of gradient color the gradient electroplating process requires a natural color transition, but there may be color differences between different batches. We finally achieved a gradient effect that satisfied Keva customers through multiple experiments and adjustment of the control parameters of the gradient area.

Challenge 3: Fineness of silk-screen LOGO the silk-screen process requires precise alignment to ensure the clarity and durability of the LOGO. We optimized the printing solution to make the

LOGO more refined and in line with the brand's high-end feel.

▲The left picture above is the actual picture of the first proofing. ▲The pictures above are the renderings and actual pictures of our multiple proofing and testing.

▲The picture above shows the final sample color confirmation and the level of detail of the silk-screen LOGO.

Finally, we successfully completed the sample production and sent it to Keva for confirmation as soon as possible.

Results and Feedback

After receiving the samples, Keva were very satisfied with the appearance and quality of the finished products, especially the gradient electroplating effect. They highly recognized our professional ability and efficient response, and finally confirmed the formal cooperation.

Keva evaluation:

"Your aluminum bottles are really great! Not only does it improve the texture of the product, but it also perfectly matches our brand tone."

▼MERRYNEWON mass production and delivery completed.

Conclusion: Why choose MERRYNEWON?

- Industry experience:Rich experience in brand cooperation, can quicklyunderstand customer needs.

- Customization ability: From concept to mass production, full process customization to meet customer personalized needs.

- Professional design: 3D rendering + proofing support to help customers see the final effect in advance.

- Efficient production: Independent factory + strict quality control to ensure product quality and delivery cycle.